Editor: Jaap Horst

Improvements were made affecting the valves, propellor reduction gears, water pump, oiling system etc. The ignition was changed to Splitdorf and Simms, with distributors mounted on the ends of the camshafts. Output was rated at 420HP, dry weight was 1248lb (550kg). The drawings below wil clearify some of the construction details, also for the Bugatti engines, which were not so very different.

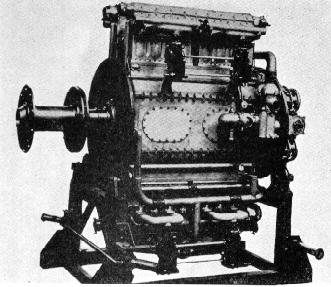

The crankshafts are made up of two halves, as in the Bugatti. Each half forms a four-cylinder shaft with the throws all in one plane. The two halves are assembled at right angles. In assembilng the completed crankshafts in the crankcase they are placed in such relation that if No.8 crank left is on top dead centre, No.8 crank right will be 45 degree past bottom dead centre!

All bearings, including the connecting rod bearings are undercut, and thereby shorten the over-all length of the engine by about 5 in. (25cm)

Click on a picture to see an enlargement!

Plans were made and production was started in a big way at the Duesenberg plant, with about 2000 planned, and maybe as much as 10000. When some 40 were built the end of the war came and production was stopped. As far as I know none of these were ever used in aircraft.

The first U-16 was rated at 480HP at 2150rpm, built in similar fashion to the Bugatti and the King-Bugatti designs. Bore and stroke were 108x160mm, displacement 1430cu.in (24 litre). Compression ratio was 5.5 to 1, weight 1100lb.

The magnesium pistons were fitted with three rings, two above and one below the piston pin, the latter serving as an oil scraper. Four sections of aluminium and magnesium comprised the crankcase. Compare these details with those of the Bugatti U-16!

The first one was a combination of two U16's (of Breguet U.24 type) in line. however with the aft one higher than the forward. When it was shown in 1920 it was the worlds most powerful aircraft"engine" rated at 1000HP, and therefore attracted quite some attention. The crankshaft gearing of the U-16's was now external, not internal as before. Important here was also that the gearing was not fixed, if one row of 8 cylinder should fail, a mechanism very common to that found on a starter engine, would declutch this part of the engine, enabling the power-plant to run at 3 quarter power.

This twin U-16 unit was used and flew in the Breguet Leviathan.

At the Salon de l'Aeronautique of December 1924, Breguet presented what was certainly the ultimate development of the Bugatti engine. This was a H-32, constructed out of 4 banks of 8, which like in the twin U-16, could all be declutched. Bore and stroke were 108x160mm. Displacement 2860 cu.in. (48 litre) During a test in 1925 it was rated at 950HP, and a maximum of 1015HP. Total weight was 2398lb (1100 kg)

However the engine was still heavy for the output, and was not used. Breguet got out of engine manufacturing.

A King-Bugatti engine can be seen at the National Air Museum of the Smithsonian Institution in Washington D.C., and one in the USAF museum at the Wright-Patterson AF Base at Fairborn, Ohio.

Become a member of the Bugatti Aircraft Association!

Breguet U-sixteen

When U-16 units were tested, the structural weakness of the thin cast-iron cylinder walls was revealed, also found by King 2 years earlier. The bore therefore was reduced from 110 to 108 mm. Ettore by 1921 took his hands of the project, and was replace by an engineer named Vullierme. One of his improvements was to put in steel cylinders.Breguet U-sixteen: Type U.24

This later model had bore and stroke of 108x163mm, making 1457 cu.in. displacement. The engine was reported to develop 600HP at 2800rpm. As in the earlier model, each row of eight cylinders had its own crankshaft, driving the common propellor shaft through a clutch device that enabled either of the eight-cylinder units to de-clutch itself in case of failure. This however would unbalance the engine, as the Bugatti U-16 was designed with both crankshafts at a fixed position, the one to the other! An important change from the Bugatti engine was that each crankshaft was made up in four sections and supported upon five roller bearings. The Bugatti had nine plain bearings.

The cylinders were machined out of a solid block of steel. The two inlet and three exhaust valves in each cylinder were operated directly by the twin cams of an overhead camshaft, without tappets or return springs. The return of the valves was accomplished by compressed air supplied by a small pump. Oil was circulated through the stems of the exhaust valves for cooling. The connecting rods wre made from duralumin and had tubular shank sections.Breguet U-sixteen: Type U.24bis

This one differed from the U.24 mainly in the increased stroke of 170mm, making a displacement of 1518cu.in (25litre). The cylinders were made up in two sections, the heads being of bronze, and the remainder of steel. The two spark plugs of each cylinder were arranged side-by-side (as in the King-Bugatti), not on opposite sides, as before. Instead of four sections, the crankcase was made of two sections, of Alpax metal. The piston was made in two sections, and instead of one air pump for returning the valves, two pumps were used, and these were mounted at the rear.

Breguet Quadimoteur Type A

Breguet Quadrimoteur Type B

The steel cylinders were provided with duralumin water jackets. There were two inlet and two exhaust valves in each cylinder! A serious change from the Bugatti design! The aluminium pistons were fitted with two compression rings and one oil-sraper ring. Two oil pumps, two fuel pumps and two water pumps were mounted on the reduction gear housing and driven from the propellor shaft (reduced at 2 to 1 from the crankshafts). Each row of eight cylinders was supplied by two carburetors!

Museum engines

The best place to visit is the Musee de l'air at Chalais-Meudon, 2 rue des Vertuajadins, Meudon, just outside the Paris boundaries in the south west direction. There is a French U-16 engine here to be seen, as as well as two Breguet-Bugatti engines and a 1.5 litre Brescia engine. Of the Breguet Bugattis at least one is of the H-32 type.

Aircraft Engines / Aircraft / License Aircraft Engines / Bugatti powered / Bibliography / index